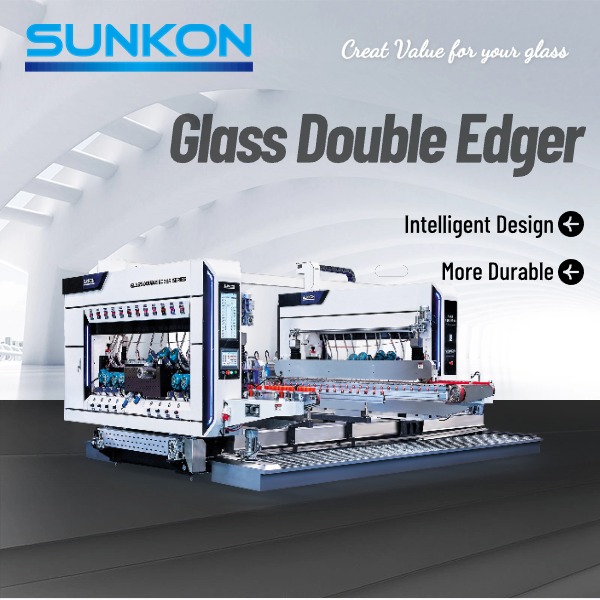

HIGH SPEED GLASS DOUBLE EDGING MACHINE 副本

HIGH SPEED GLASS DOUBLE EDGING MACHINE 副本

- Glass straight line double edging machine means double edged glass grinding machine, which can finish rough grinding, fine grinding, polishing and chamfering at one time.

-

- In general, we have glass double edger grinding machines with 24 motors, 26 motors, and 28 motors for you to choose from. In addition, we use specialized glass machines to meet the specific needs of our customers.

-

-

- Double side glass edging polishing Machine is suitable for processing construction Glass, architectural glass, doors and windows, insulating glass, home appliance glass, and LOW-E glass.

-

-

-

- Glass double edger adopts double servo main driver, which guarantees excellent precision and accuracy. As well as high speed opening and closing with a servo motor .

-

| Model | CGSZ2425 | CGSZ2442 |

| No. of spindles | 24 | 24 |

| Glass Thickness | 3 - 25mm | 3-25mm |

| Min Processed Size | 350*350mm | 350*350mm |

| Max Processed Size | 2500mm | 4200mm |

| Process Speed | 1-20m/min | 1-20m/min |

| Speed of width adjustment | 1-15m/min | 1-15m/min |

| Working Height | 920±30mm | 920±30mm |

| Grinding quantity of bottom | 1-3mm | 1-3mm |

| Grinding quantity of chamfer | 1-3mm | 1-3mm |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Total Power | 70kw | 70kw |

For more details about glass machinery, please feel free to contact us, we have more models to meet your needs, or we have one stop solution for glass deep-processing equipment.

PLC control

Fast glass double edge adopts famous PLC brand "Inovance" controlled, match with touch screen, which is easy operation for technician ,the data setting on human touch screen and all the information of glass can show on the controlling center. Processing width, thickness, upper arris,grinding amount and processing speed can adjust automatically.

High quantity motors

Glass Straight Line Double Edging Machine adopt famous motor brand “CDQC”, with reasonable layout of wheels to make good performance on glass edge. The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing.

Servo motor driver system

High speed glass double edger for main drive double servo motor with large-load parallel gear reducers and adopts the most advanced servo communication control technology to make sure excellent synchronism and high transmission.

Open-close for glass processing width

High precision glass double edger adopts servo motor for adjusting the opening and closing for processing different glass size, to make sure smooth running even in high speed.

Pneumatic polishing

All polishing wheels on double side glass edging polishing Machine adopt pneumatic polishing, and the grinding head is in and out pneumatically at the same time, equipped with high-precision motor carriage, to protect better polishing effect.

LOW-E film removing (OPTIONAL)

This spindle is used to remove LOW E film of the top on the flat glass edge. Double side glass edging polishing Machine adopts advanced structure to make sure stable and high quality low-e removing result. Generally speaking, this structure is optional between enhance polishing and low-e removing. Double edging machine for glass with LOW-E removing connected with glass tempering machine, glass washing machine, glass laminating machine and tec.