CGX261P Glass Straight Line Beveling Machine with PLC Control

CGX261P Glass Straight Line Beveling Machine with PLC Control

-

Glass straight-line beveling machine is suitable for processing bevel & bottom edge of glass sheet withvarious size and thickness.

-

-

The base, front and rear beams, beds and grinding heads are of casting materials(annealed to prevent deformation),Which can bear large loads and has stable performance.

-

-

-

- It's the best machine for processing craft glass, decoration and furniture glass,doors and windows,bathroom mirror and cosmetic mirror

-

| Model | CGX261 |

| Glass Thickness | 3 - 19mm |

| Min Processed Size | 100*100mm |

| Max Processed Size | 2500*2500mm |

| Transmission Speed | 0.5-5m/min |

| Bevel angle | 0-25° |

| Max Hypotenuse width | 40mm |

| Power | 21.5KW |

| Weight | 4000kg |

| Land occupation | 6500*1300*2500mm |

For more details about glass machinery, please feel free to contact us, we have more models to meet your needs, or we have one stop solution for glass deep-processing equipment.

Frequency inverter

Adopt the frequency inverter to ensure keep the glass edging machine more stable while processing the heavy and overload size glass.

ABB electric

Adopt the ABB electric with neat line layout which make the glass machine more safety and running smoothly

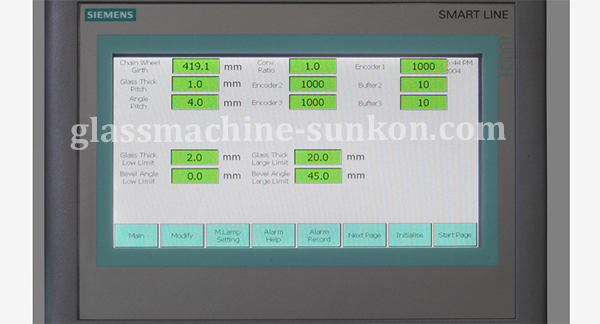

SIEMENS touch screen

The glass straight line edging machine use SIEMENS PLC and touch screen to show glass thickness , speed and more information which is easy for operation.

Rear pads cleaning device

Adopt the rear pads cleaning device to ensure that the plates is clean and the polishing effect is better.

Independence felt wheels

Adopt independence felt wheels polishing ,which make the effect of glass better.

stainless steel water

Adopt of 2 piece of quality stainless steel water tank .One for water circulation ,The other one for cerium polishing