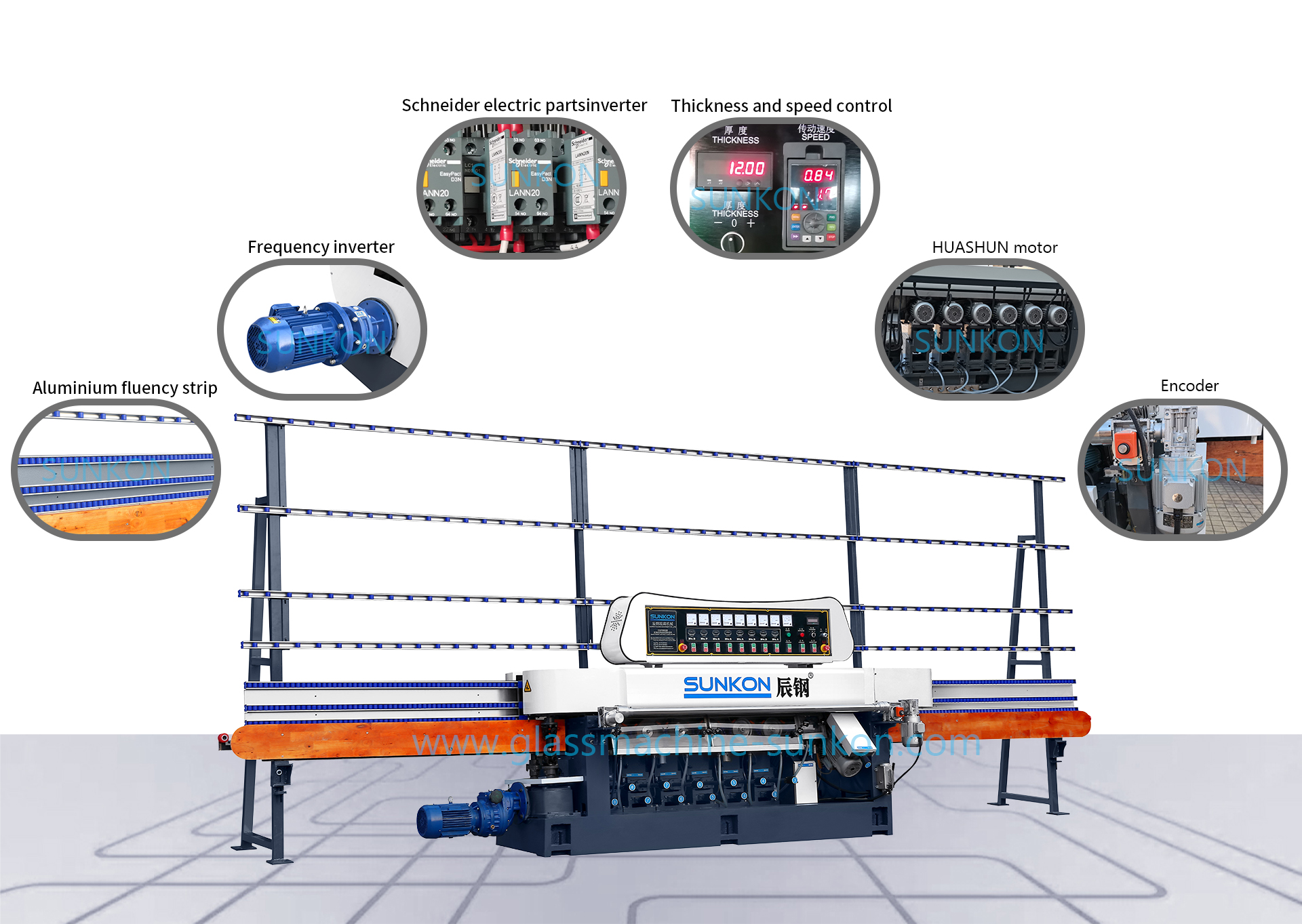

CGY8320 Glass Straight Line Pencil Edging Machine

CGY8320 Glass Straight Line Pencil Edging Machine

VIDEO

DESCRIPTION

■CGY8320 Its suitable for processing straight-line round edge of glass sheet, and OG edge with various size and thickness.

■Coarse grinding, fine grinding, polishing and chamfering can be completed in one time.

■The base, front and rear beams, beds and grinding heads are of casting materials (annealed to prevent deformation), Which can bear large loads and has stable performance.

■The front and rear plates are made of 40Cr forged materials, whose surfaces is much more durable with high-frequency quenching treatment after fine grinding.

■Production speeds is adjusted by step-less motor.

■It is the best glass grinding equipment for processing craft glass, furniture glass, and architecture glass.

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

WHEELS PLACEMENT

| Glass Thickness | 3-19mm |

| Min Processed Size | 80*80mm |

| Max Processed Size | 3000*3000mm |

| Process Speed | 0.5-6m/min |

| Weight | 4000kg |

| Total Power | 19kw |

| Land occupation | 7300×1000×2500mm |

MAIN STRUCTURE PARTS

01 QINGZHU Gear

Adopt the famous brand “QIANGZHU” gear box to make the machine more stable.

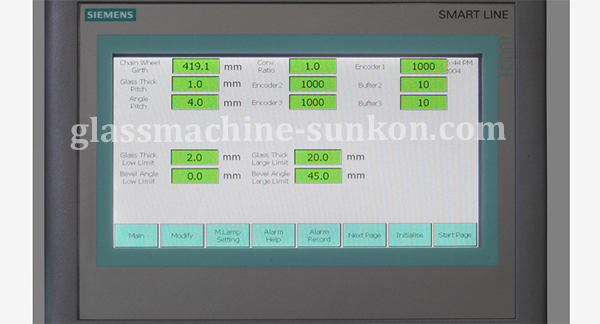

02 Siemens PLC touch screen

Adopt SIEMENS PLC and touch screen to show glass thickness , speed and more information which is easy for operation.

03 Schneider Electric

Adopt the Schneider electric with neat line layout which make the machine more safety and running smoothly.

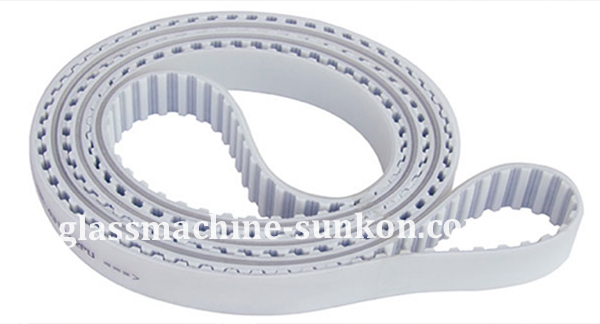

04 High Quality Timiling Belt

Adopt the high quality timing belt to convey the glass,which has longer service life and more accurate.

05 CDQC Grinding Motors

Adopt famous brand CDQC for the grinding motors,durable and reliable for use.

06 Side pressure correction device

Input structure is with side pressure correction device, which is easy for adjusting and maintenance.

07 Extra cutting quantity detect device

When the extra edge of coming glass touches this device, it will pass signal to PLC and the machine will be informed to slow down for this extra edge. Then the glass grinding and polishing quality will be much better.

CUSTOMER CASE