Europe style for Furniture Glass Double Edging Machinery - CGSZ2442 Full Servo High Speed Glass Double Edging Machine – SUNKON

Europe style for Furniture Glass Double Edging Machinery - CGSZ2442 Full Servo High Speed Glass Double Edging Machine – SUNKON

Europe style for Furniture Glass Double Edging Machinery - CGSZ2442 Full Servo High Speed Glass Double Edging Machine – SUNKON Detail:

DESCRIPTION

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

WHEELS PLACEMENT

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Glass Thickness | 3-25mm |

| Min Processed Size | 350*350mm |

| Max Processed Size | 4200mm |

| Process Speed | 15m/min |

| Working Height | 920mm |

| Total Power | 70kw |

MAIN STRUCTURE PARTS

01 The Whole Machine Uses Swiss ABB Motor

Adopt ABB special high-speed frequency conversion motor, cooperate with the famous domestic grinding wheel brand Qixingshi special grinding wheel, the grinding speed is fast; the processing speed of 5-8MM glass is as high as 15-18m/min; The glass speed of 8-12MM can reach 12-15m/min.

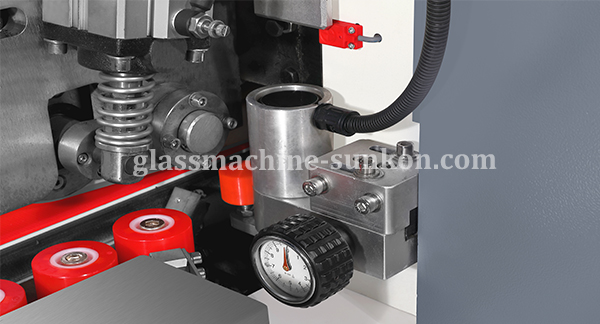

02 Lower Chamfering Secondary Transmission Structure

The precision ball screw is used to lift the whole, and with the servo motor control, all the chamfers will be the same size, and the chamfering error of the processed plate is small. It can prevent the phenomenon of burning the motor caused by the leakage of the waterproof sleeve due to the common use of the motor under the structure.

03 Double Servo Drive Structure

The fixed side and the moving side are each driven by a set of servo motors. Starlight’s latest k series turbine box with high torque output ratio has a large transmission force. Compared with the universal joint transmission structure, the direct-connected transmission structure has a small transmission gap, which ensures the fixed side. Synchronization with moving side drive

04 Open-close Control For Glass Processing Width

Siemens servo motor adjusts the opening and closing of the machine to make sure smooth running even in high speed.

05 Extra Cutting Quantity Detect Device

When the extra edge of coming glass touches this device, it will pass signal to PLC and the machine will be informed to slow down for this extra edge. Then the glass grinding and polishing quality will be much better.

06 Entry Side Servo Adjustment Function

Automatic adjustment of the grinding amount at the feeding end: according to the size and thickness of the glass, the automatic adjustment of the grinding amount structure can be added to the incoming end of the edger, which can reduce the chipping and fragmentation caused by glass processing and ensure the quality of glass processing. It can also reduce the dependence on people.

CUSTOMER CASE

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for Europe style for Furniture Glass Double Edging Machinery - CGSZ2442 Full Servo High Speed Glass Double Edging Machine – SUNKON , The product will supply to all over the world, such as: Danish, United States, Luxembourg, We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!