factory low price Window Double Edging - CGSY1225 Glass Pencil Double Edging Machine – SUNKON

factory low price Window Double Edging - CGSY1225 Glass Pencil Double Edging Machine – SUNKON

factory low price Window Double Edging - CGSY1225 Glass Pencil Double Edging Machine – SUNKON Detail:

DESCRIPTION

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

WHEELS PLACEMENT

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Glass Thickness | 3-12mm |

| Min Processed Size | 350*350mm |

| Max Processed Size | 2500mm(CGSY1225) |

| Process Speed | 0.5-6m/min |

| Working Height | 920mm |

| Total Power | 29kw |

MAIN STRUCTURE PARTS

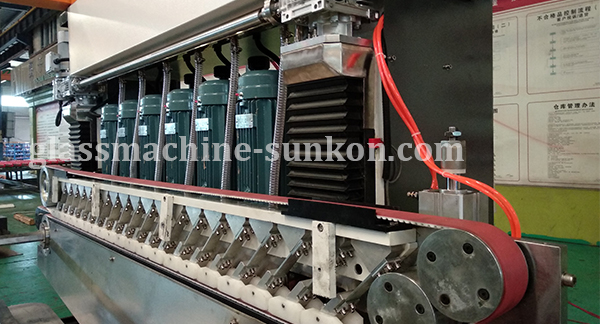

01 Reasonable Layout of wheels

Adopt famous ABB motors Enhance the grinding ability, increase the flat grinding speed, the effect is obvious for thick glass

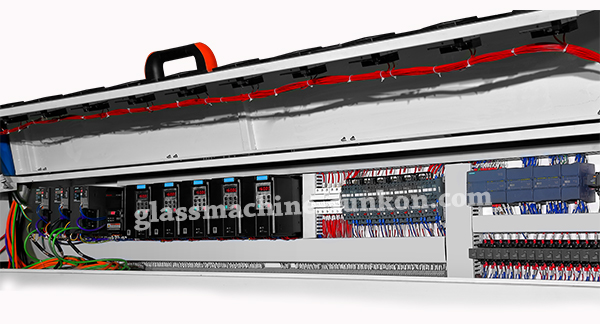

02 Tidy circuit box

Adopts Schneider electrical components and Siemens PLC. All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

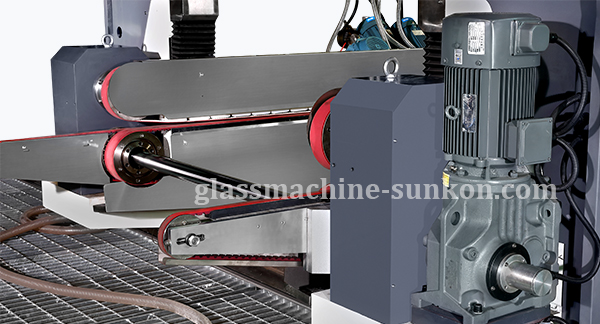

03 Variable frequency drive system

Frequency inverter with mandrel screw, Two big gears to make sure strong conveying.The synchronization of transmission is higher and the accuracy is more accurate.

04 Open-close control for glass processing width

The frequency conversion motor adjusts the opening and closing of the machine, which is accurate and stable, with a safety guard, the machine is more beautiful and safe.

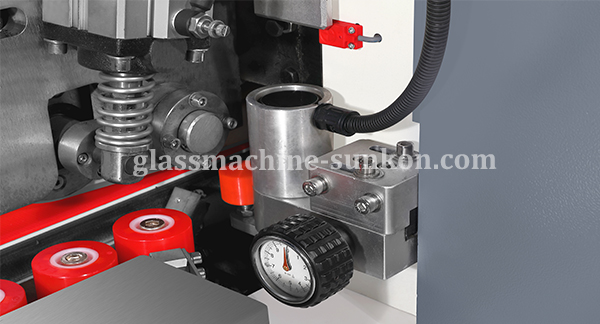

05 Extra cutting quantity detect device

When the extra edge of coming glass touches this device, it will pass signal to PLC and the machine will be informed to slow down for this extra edge. Then the glass grinding and polishing quality will be much better.

06 Side pressure correction device

Input structure is with side pressure correction device, which is easy for adjusting and maintenance.

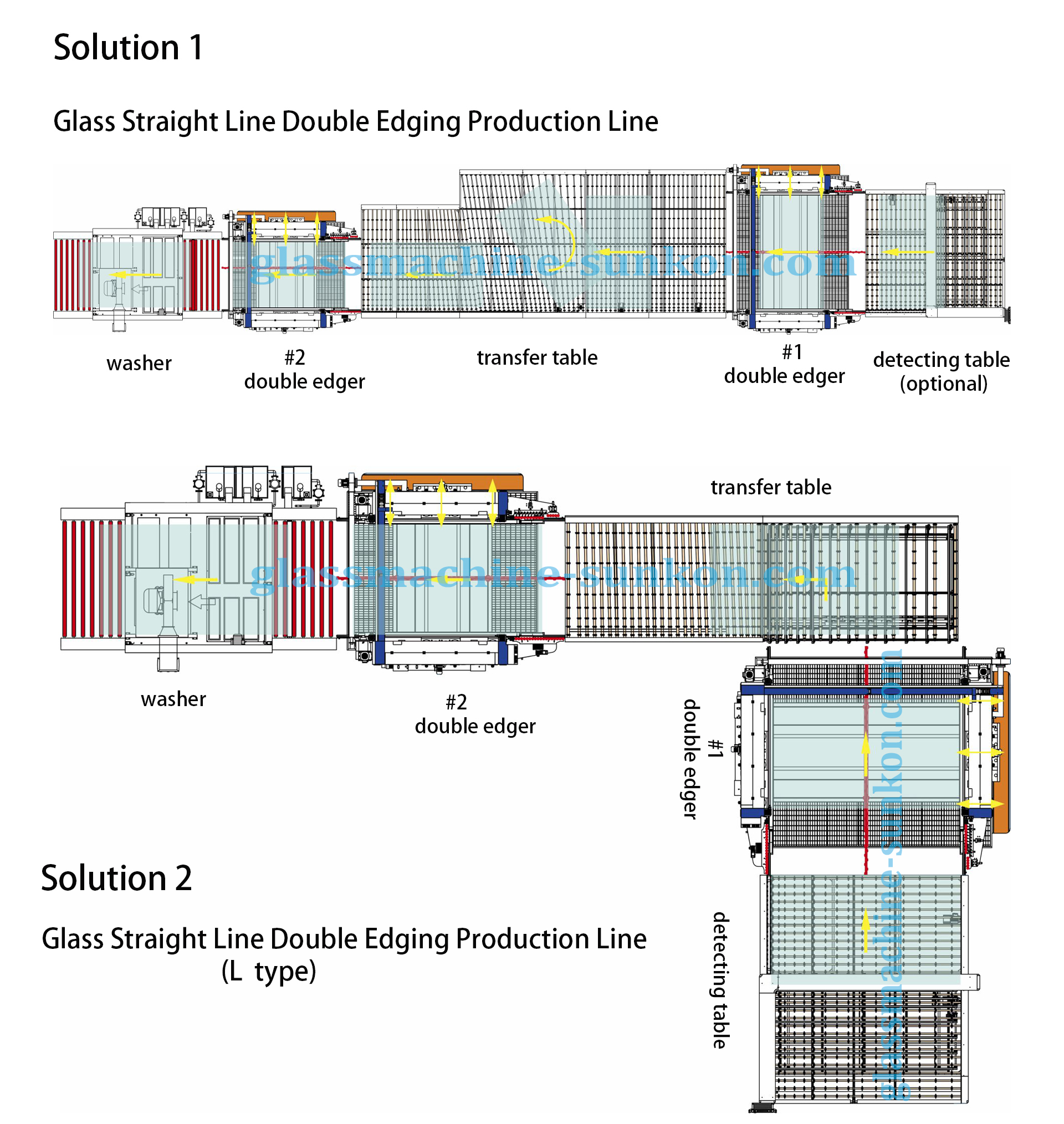

CUSTOMER CASE

Product detail pictures:

Related Product Guide:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for factory low price Window Double Edging - CGSY1225 Glass Pencil Double Edging Machine – SUNKON , The product will supply to all over the world, such as: Dubai, Cannes, Australia, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!