Factory Outlets Edge Polishing Machin For Sintered Stone - CGSC641 Stone Edging Machine – SUNKON

Factory Outlets Edge Polishing Machin For Sintered Stone - CGSC641 Stone Edging Machine – SUNKON

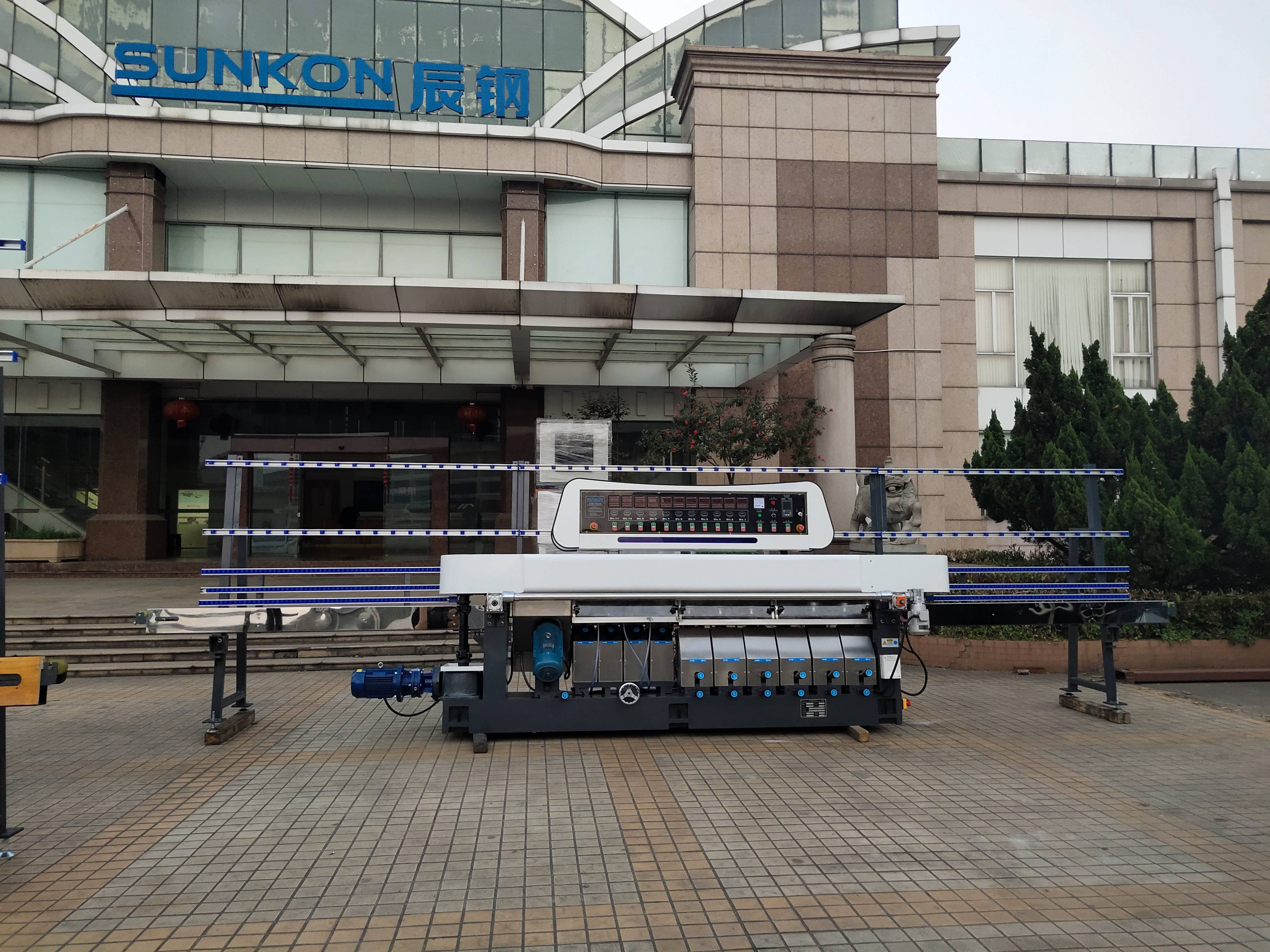

Factory Outlets Edge Polishing Machin For Sintered Stone - CGSC641 Stone Edging Machine – SUNKON Detail:

DESCRIPTION

■CGSC11 It’s suitable for processing various size and thickness of all kinds of stone, marble and granite. It equips with diamond wheel, water abrasive discs, polish cotton discs, connecting snail lock to process 45 degree angle, flat edge, thicken bottom edge, skirting line etc.

■Coarse grinding, fine grinding, polishing and chamfering can be completed in one-time processing.

■The base, front and rear beams, beds and grinding heads are of casting materials (annealed to prevent deformation), Which can bear large loads and has stable performance.

■Spindle base structure is with new design, made of 20mm thick steel panel, stable and indeformable, make sure motor without vibration even when processing thick and big stone piece.

■ Machine capacity equals to workload of 15 men in normal processing, what’s more, machine processing avoids artificial effect well.

■ It is the best stone grinding equipment for batch production in stone processing industry.

TECHNICAL DATA

|

NAME |

DATE |

| Max.Glass size | 2500×2500mm |

| Min.Glass size | 100×100mm |

| Glass thickness | 3-30mm |

| Transmissinon speed | 0.5-6m/min |

| Bevel angle | 0~25° |

| Max.hemline grinding | 3mm |

| Max. arris grinding | 2.5mm |

| Power | 19.5KW |

| Weight | 2800kg |

| Land occupation | 7000×1000×2500mm |

WHEELS PLACEMENT

|

NO |

Motor |

Power (KW) |

GRINDING WHEEL |

|

name |

|||

|

1 |

profile rough |

4.5 |

Diamond wheel |

|

2 |

profile rough |

4.5 |

Diamond wheel |

|

3 |

Polishing |

3 | Water abrasive plate |

|

4 |

Polishing |

3 |

Water abrasive plate |

|

5 |

Polishing |

3 | Water abrasive plate |

|

6 |

Polishing |

3 | Water abrasive plate |

|

7 |

profile rough |

3 | Diamond wheel |

|

8 |

Polishing |

3 | Water abrasive plate |

|

9 |

Polishing |

3 | Water abrasive plate |

|

10 |

Polishing |

3 | Water abrasive plate |

|

11 |

front chamfer cutting |

5.5 |

blade |

MAIN STRUCTURE PARTS

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for Factory Outlets Edge Polishing Machin For Sintered Stone - CGSC641 Stone Edging Machine – SUNKON , The product will supply to all over the world, such as: Russia, Hungary, Honduras, We have developed large markets in many countries, such as Europe and the United States, Eastern Europe and Eastern Asia. Meanwhile with the powerful predominance in persons with ability, strict production management and business concept.we constantly carry on self-innovation, technological innovation, managing innovation and business concept innovation. To follow the world markets fashion, new products are kept on researching and providing to guarantee our competitive advantage in styles, quality, price and service.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.