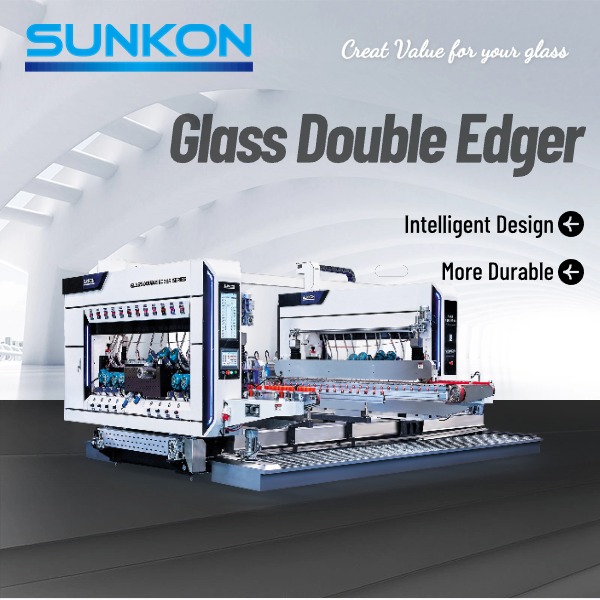

CGSZ2442 FULL SERVO HIGH SPEED GLASS DOUBLE EDGING MACHINE

CGSZ2442 FULL SERVO HIGH SPEED GLASS DOUBLE EDGING MACHINE

-

-

- This type--full servo controlled glass double edging machine adopts Inovance PLC for main driving, opening and closing , and all grinding motors. which is easy operation and labor saving.

-

- Glass straight line double edging machine means double edged glass grinding machine, which can finish rough grinding, fine grinding, polishing and chamfering at one time.

-

- In general, we have glass double edger grinding machines with 24 motors, 26 motors, and 28 motors for you to choose from. In addition, we use specialized glass machines to meet the specific needs of our customers.

-

-

- Double side glass edging polishing Machine is suitable for processing construction Glass, architectural glass, doors and windows, insulating glass, home appliance glass, and LOW-E glass.

-

-

-

- Glass double edger adopts double servo main driver, which guarantees excellent precision and accuracy. As well as high speed opening and closing with a servo motor .

-

| Model | CGSZ2425 | CGSZ2442 |

| No. of spindles | 24 | 24 |

| Glass Thickness | 3 - 25mm | 3-25mm |

| Min Processed Size | 350*350mm | 350*350mm |

| Max Processed Size | 2500mm | 4200mm |

| Process Speed | 1-20m/min | 1-20m/min |

| Speed of width adjustment | 1-15m/min | 1-15m/min |

| Working Height | 920±30mm | 920±30mm |

| Grinding quantity of bottom | 1-3mm | 1-3mm |

| Grinding quantity of chamfer | 1-3mm | 1-3mm |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Total Power | 70kw | 70kw |

For more details about glass machinery, please feel free to contact us, we have more models to meet your needs, or we have one stop solution for glass deep-processing equipment.

High performance intelligent mechanical controller AC801

PLC control

The first manufacturer in the industry to use medium-sized PLC- INOVANCE AC801, using the I5 CPU, with stronger computing and execution capabilities. (Baud rate up to 100 Mbit/s (100Base-TX)); Single EtherCAT port, up to 48 axes, 128 slave stations. The Ethernet port of the AC801 controller can be point-to-point connected to the computer, HMI, servo, etc., through one Ethernet cable.

Inverter individual drive

The grinding head motor is driven separately, and a frequency converter drives a grinding head motor separately, avoiding the situation that several grinding head motors cannot work due to the damage of a frequency converter, enhancing the protection of the motor and extending the service life.

High quantity motors

Glass Straight Line Double Edging Machine adopt famous motor brand “CDQC”, with reasonable layout of wheels to make good performance on glass edge. The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing.

Servo motor driver system

High speed glass double edger for main drive double servo motor with large-load parallel gear reducers and adopts the most advanced servo communication control technology to make sure excellent synchronism and high transmission.

Open-close for glass processing width

High precision glass double edger adopts servo motor for adjusting the opening and closing for processing different glass size, to make sure smooth running even in high speed.

Servo controlled polishing

All polishing wheels adopt servo controlled, and the polishing head is in and out pneumatically at the same time, equipped with high-precision motor carriage, the polishing effect is guaranteed

LOW-E film removing (OPTIONAL)

This spindle is used to remove LOW E film of the top on the flat glass edge. Double side glass edging polishing Machine adopts advanced structure to make sure stable and high quality low-e removing result. Generally speaking, this structure is optional between enhance polishing and low-e removing. Double edging machine for glass with LOW-E removing connected with glass tempering machine, glass washing machine, glass laminating machine and tec.