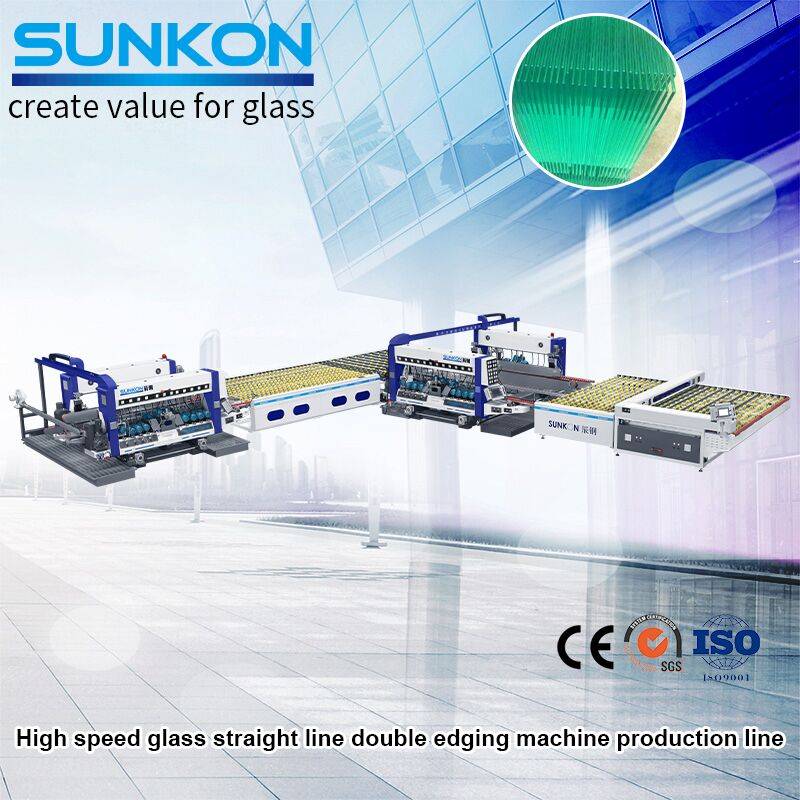

High Quality for Line Polish Machin For Marble - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON

High Quality for Line Polish Machin For Marble - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON

High Quality for Line Polish Machin For Marble - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON Detail:

DESCRIPTION

■The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing.

■Installed with excellent linear guide and screw mandrels which ensures the processing precision. Bracket of movable side system is W frame design, which increases the accuracy of movements and the degree of stability; also it can extend the life time of the linear rack.

■All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

■Position corrected device has been added on the machine, which solves the deviate problem of small glass, and truly realize intelligent operation of connected machines when transferring glass.

■Lifting distance of upper press beam is large for replacing wheels easily.

■Siemens PLC control with touch screen, the data setting and the grinding status of glass can be showed on the controlling center. Processing width, thickness, and lifting of upper arris are adjusted automatically.

TECHNICAL DATA

| Glass thickness |

3~25 mm |

Max. arris grinding |

3mm |

|

Min. processed size |

300*300 mm |

Process speed |

1~15m/min |

|

Max. processed size |

3000*2500mm |

working height |

920mm |

|

Max. hemline grinding |

2mm(single line) |

Voltage/frequency |

380V/50HZ or customized |

|

compress air |

0.7Mpa |

Total power |

85kw |

WHEELS PLACEMENT

|

NO |

Wheel use |

Power (KW) |

Motor brand |

GRINDING WHEEL |

|

| Diameter(mm) | name | ||||

|

1 |

Rough grinding for bottom |

4 |

CDQC |

175 |

Diamond wheel |

|

2 |

Rough grinding for bottom |

4 |

CDQC |

175 |

Diamond wheel |

|

3 |

Rough grinding for chamfer |

3 |

ABB |

175 |

Resin wheel |

|

4 |

Rough grinding for chamfer |

2.2 |

ABB |

175 |

Resin wheel |

|

5 |

Polishing for chamfer |

3 |

ABB |

175 |

Resin wheel |

|

6 |

Low-E |

3 |

ABB |

150 |

Low-E wheel |

MAIN STRUCTURE PARTS

Product detail pictures:

Related Product Guide:

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for High Quality for Line Polish Machin For Marble - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON , The product will supply to all over the world, such as: France, India, Auckland, With the best technological support, we have tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!