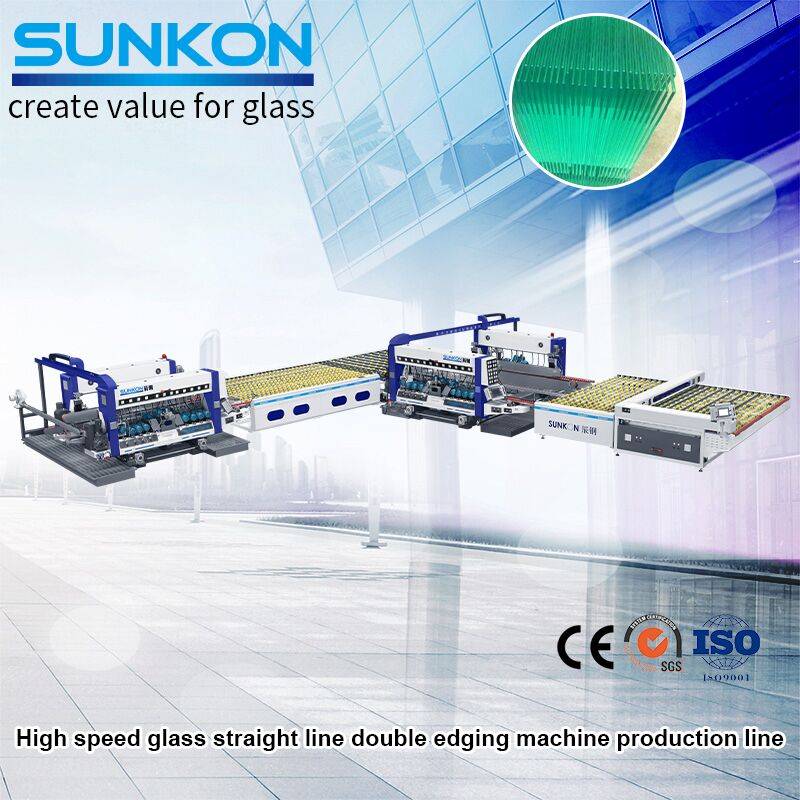

Massive Selection for Furniture Glass Double Edging Equipment - CGSZ2225 22 Motors Glass Double Edging Machine – SUNKON

Massive Selection for Furniture Glass Double Edging Equipment - CGSZ2225 22 Motors Glass Double Edging Machine – SUNKON

Massive Selection for Furniture Glass Double Edging Equipment - CGSZ2225 22 Motors Glass Double Edging Machine – SUNKON Detail:

DESCRIPTION

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

WHEELS PLACEMENT

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Glass Thickness | 3-25mm |

| Min Processed Size | 350*350mm |

| Max Processed Size | 2500*2500mm |

| Process Speed | 1-12m/min |

| Working Height | 920mm |

| Total Power | 58kw |

MAIN STRUCTURE PARTS

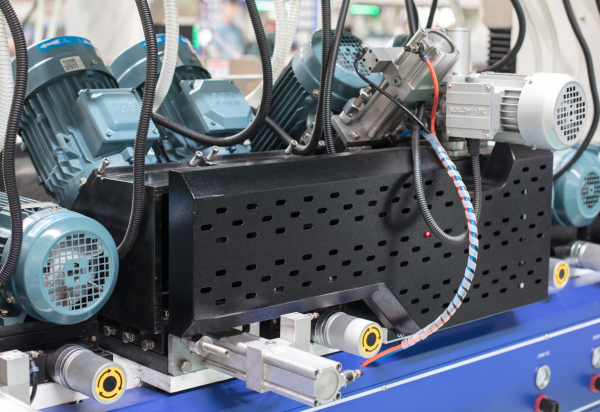

01 Reasonable Layout of wheels

Adopt famous motor brand “ABB” , and reasonable layout of wheels to make good performance on glass edge. The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing

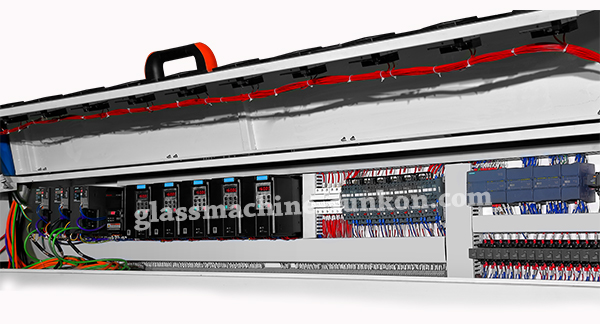

02 Tidy circuit box

Adopts Schneider electrical components and Siemens PLC. All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

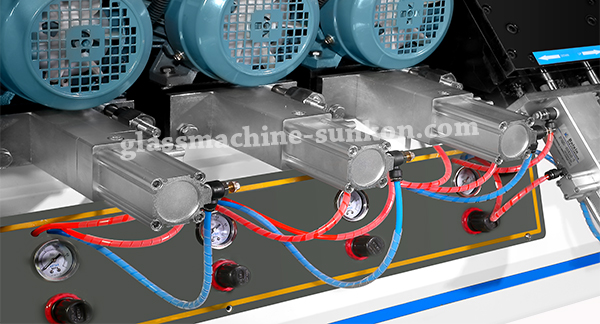

03 Pneumatic polishing

All polishing wheels adopt pneumatic polishing, and the polishing head is in and out pneumatically at the same time, equipped with high-precision motor carriage, the polishing effect is guaranteed

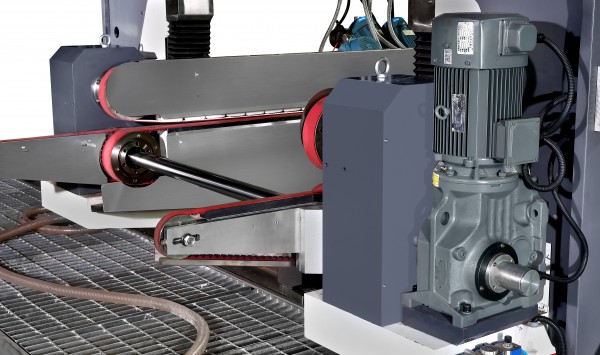

04 Variable frequency drive system

Screw drive, two large gears ensure strong conveying. The transmission synchronization is higher and the precision is more accurate.

05 Chamfer structure

The chamfer adopts a secondary transmission structure, and the chamfer motor is placed on the upper side at an angle of 45°, which greatly avoids the phenomenon that the traditional chamfer motor is placed down at 45° and caused the motor to be burned out by water.

06 Side pressure correction device

Input structure is with side pressure correction device, which is easy for adjusting and maintenance.

CUSTOMER CASE

Product detail pictures:

Related Product Guide:

We often persist with the theory "Quality To start with, Prestige Supreme". We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Massive Selection for Furniture Glass Double Edging Equipment - CGSZ2225 22 Motors Glass Double Edging Machine – SUNKON , The product will supply to all over the world, such as: Uruguay, Luxemburg, Lebanon, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We've been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.