OEM/ODM China Glass Door Processing Machinery - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON

OEM/ODM China Glass Door Processing Machinery - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON

OEM/ODM China Glass Door Processing Machinery - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON Detail:

VIDEO

DESCRIPTION

APPLICATION

Construction Glass

Industrial Glass

Door and window Glass

Furniture Glass

Appliance Glass

WHEELS PLACEMENT

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

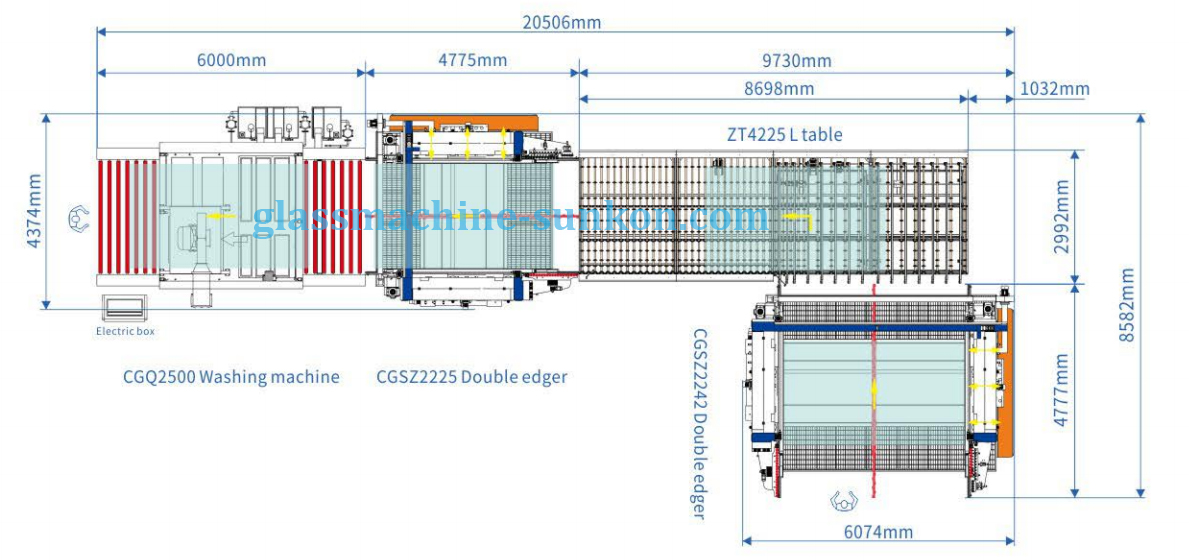

| Glass Thickness | 3-25mm |

| Min Processed Size | 350*350mm |

| Max Processed Size | 4200mm(CGSZ4225) |

| Process Speed | 1-15m/min |

| Working Height | 920mm |

| Total Power | 47kw |

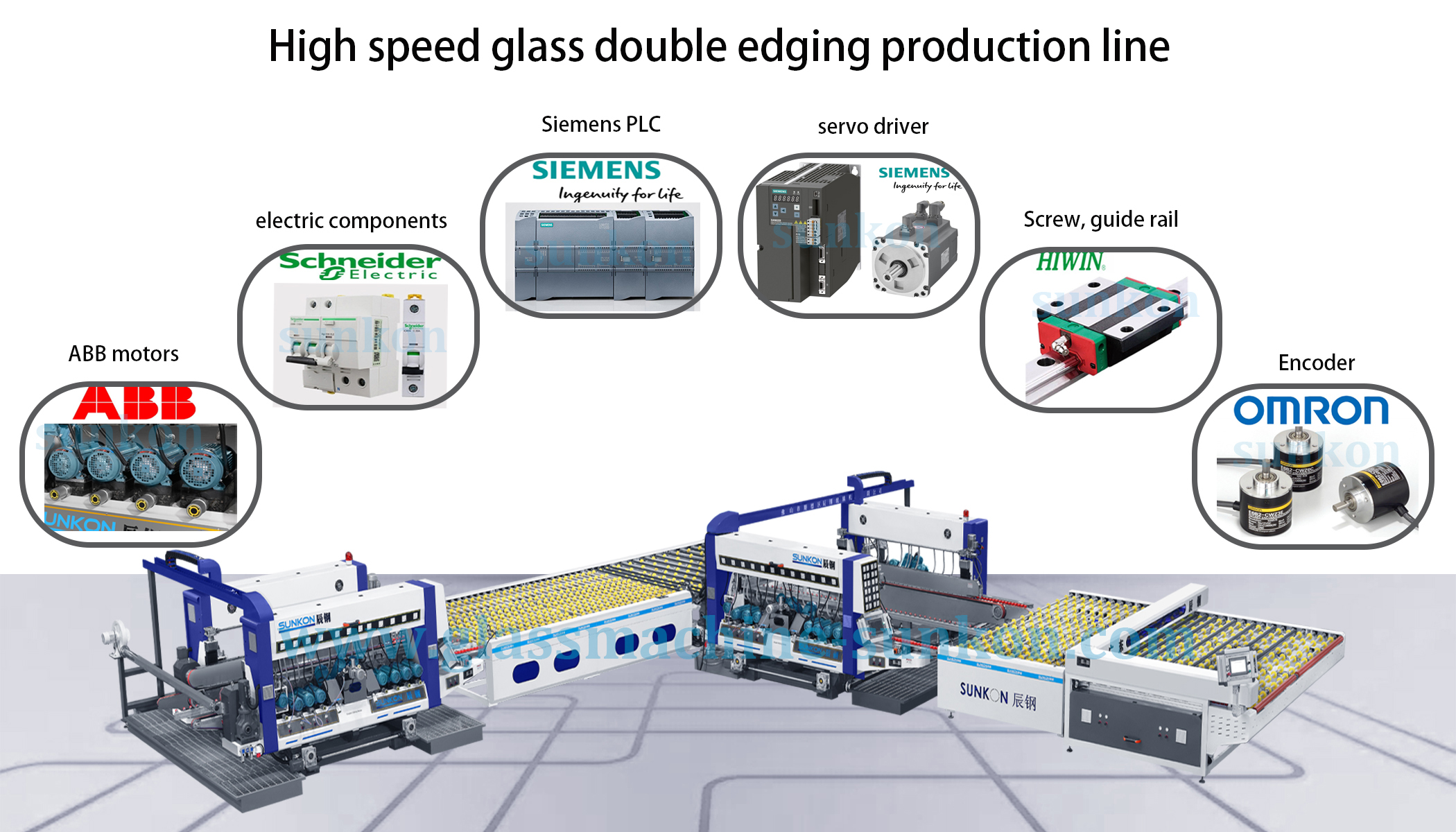

MAIN STRUCTURE PARTS

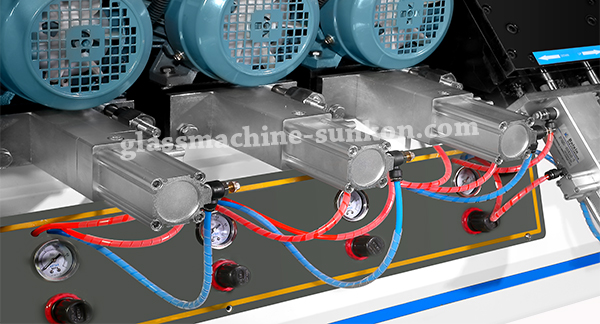

01 Reasonable Layout of wheels

Adopt famous motor brand “ABB” , and reasonable layout of wheels to make good performance on glass edge. The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing

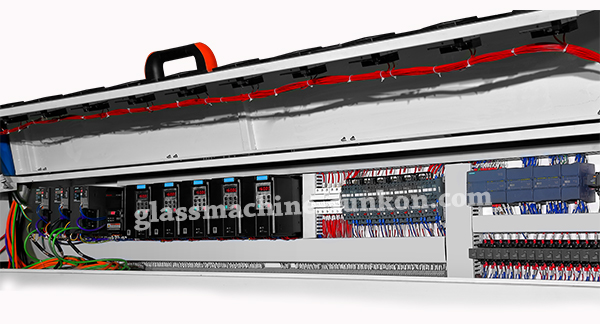

02 Tidy circuit box

Adopts Schneider electrical components and Siemens PLC. All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

03 Pneumatic polishing

All polishing wheels adopt pneumatic polishing, and the polishing head is in and out pneumatically at the same time, equipped with high-precision motor carriage, the polishing effect is guaranteed

04 Open-close control for glass processing width

Siemens servo motor adjusts the opening and closing of the machine to make sure smooth running even in high speed.

05 Extra cutting quantity detect device

When the extra edge of coming glass touches this device, it will pass signal to PLC and the machine will be informed to slow down for this extra edge. Then the glass grinding and polishing quality will be much better.

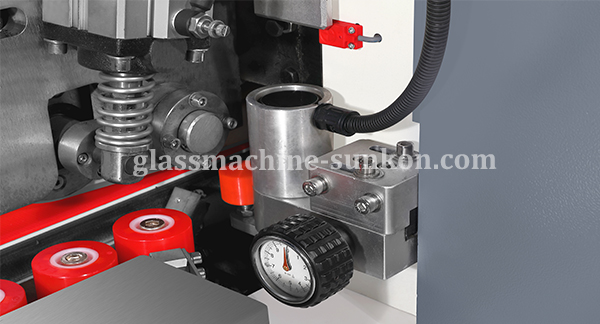

06 Side pressure correction device

Input structure is with side pressure correction device, which is easy for adjusting and maintenance.

CUSTOMER CASE

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for OEM/ODM China Glass Door Processing Machinery - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON , The product will supply to all over the world, such as: Iran, Ukraine, Bahrain, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!