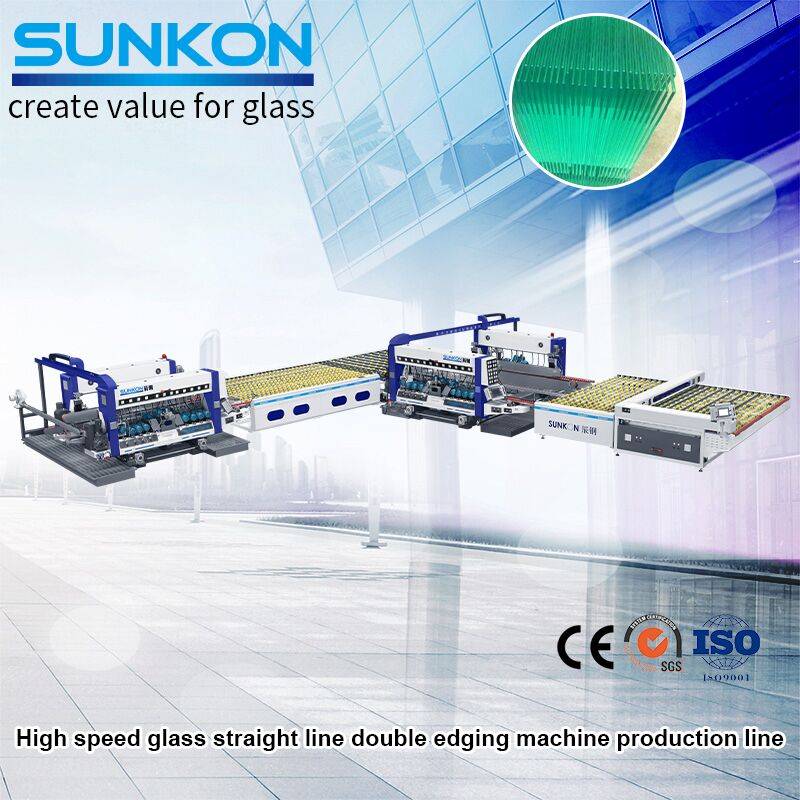

Special Price for Glass Door Edging Machines - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON

Special Price for Glass Door Edging Machines - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON

Special Price for Glass Door Edging Machines - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON Detail:

DESCRIPTION

■The double parallel straight lines’ bottom and arris of glass can be processed at one time by rough, fine grinding and pneumatic polishing.

■Installed with excellent linear guide and screw mandrels which ensures the processing precision. Bracket of movable side system is W frame design, which increases the accuracy of movements and the degree of stability; also it can extend the life time of the linear rack.

■All-in-one structure for machine and circuit box is good for waterproof, space saving and convenient for operation.

■Position corrected device has been added on the machine, which solves the deviate problem of small glass, and truly realize intelligent operation of connected machines when transferring glass.

■Lifting distance of upper press beam is large for replacing wheels easily.

■Siemens PLC control with touch screen, the data setting and the grinding status of glass can be showed on the controlling center. Processing width, thickness, and lifting of upper arris are adjusted automatically.

TECHNICAL DATA

| Glass thickness |

3~25 mm |

Max. arris grinding |

3mm |

|

Min. processed size |

300*300 mm |

Process speed |

1~15m/min |

|

Max. processed size |

3000*2500mm |

working height |

920mm |

|

Max. hemline grinding |

2mm(single line) |

Voltage/frequency |

380V/50HZ or customized |

|

compress air |

0.7Mpa |

Total power |

85kw |

WHEELS PLACEMENT

|

NO |

Wheel use |

Power (KW) |

Motor brand |

GRINDING WHEEL |

|

| Diameter(mm) | name | ||||

|

1 |

Rough grinding for bottom |

4 |

CDQC |

175 |

Diamond wheel |

|

2 |

Rough grinding for bottom |

4 |

CDQC |

175 |

Diamond wheel |

|

3 |

Rough grinding for chamfer |

3 |

ABB |

175 |

Resin wheel |

|

4 |

Rough grinding for chamfer |

2.2 |

ABB |

175 |

Resin wheel |

|

5 |

Polishing for chamfer |

3 |

ABB |

175 |

Resin wheel |

|

6 |

Low-E |

3 |

ABB |

150 |

Low-E wheel |

MAIN STRUCTURE PARTS

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for Special Price for Glass Door Edging Machines - CGSZ3025-12 High Speed Glass Straight-Line Double Edging Production Line – SUNKON , The product will supply to all over the world, such as: Sao Paulo, California, Atlanta, With a fully integrated operation system, our company has won a good fame for our high quality products, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.